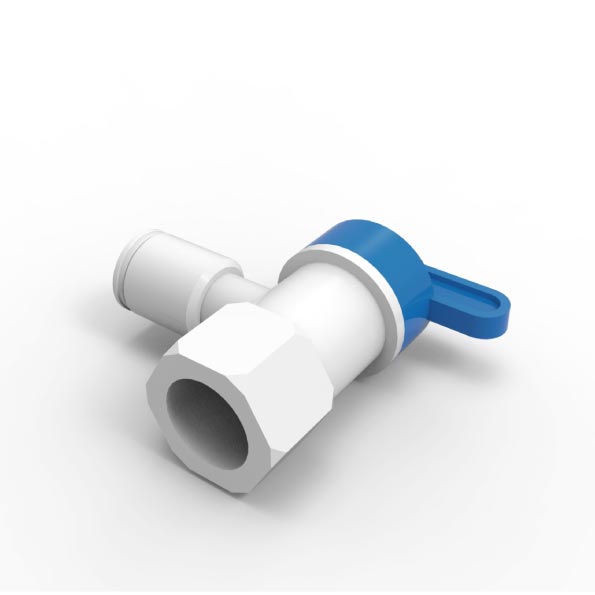

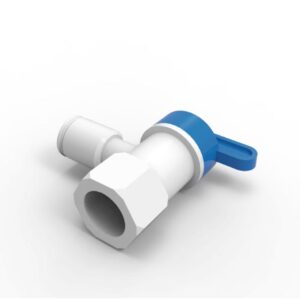

RO tank valve

1,0 ر.ع.

Reverse Osmosis (RO) Tank Valve:

An essential component for connecting the storage tank to the RO system, made from durable food-grade plastic to ensure the safety of drinking water. Lightweight, cost-effective, and easy to install, offering reliable and long-lasting performance.

A commonly used component in reverse osmosis (RO) systems, the storage tank valve is designed to securely connect the RO storage tank to the filtration system. Constructed from durable, food-grade plastic, this valve ensures both safety and reliability, meeting the standards required for potable water applications.

Key Features:

- Durable Material: Made from high-quality, food-grade plastic that resists wear and corrosion.

- Lightweight and Cost-Effective: Provides an economical solution without compromising on performance or quality.

- Safe for Drinking Water: Ensures no contamination, maintaining the purity of the filtered water.

- Simple Installation: Designed for quick and easy connection to the RO storage tank and system.

This valve is a critical component for maintaining the efficiency and safety of your reverse osmosis system, offering reliable operation and long-lasting performance.

FAQs

In a reverse osmosis (RO) system, the tank valve serves a crucial role in isolating the storage tank from the rest of the system. This isolation is particularly beneficial during routine maintenance or servicing, as it allows for work to be performed on the RO unit without the need to empty the storage tank.

Additionally, the tank valve enables the user to control the flow of water from the storage tank to the faucet, ensuring that water is dispensed only when needed. This control helps maintain system pressure and prevents unnecessary water waste.

Overall, the tank valve enhances the efficiency and convenience of the RO system by providing easy access for maintenance and controlled water flow during usage.

Yes, RO tank valves are generally safe for drinking water, provided they are constructed from materials approved for potable water use. Common materials include food-grade plastics like UPVC and ABS, as well as metals such as 316 stainless steel and certain copper alloys. These materials are recognized for their safety in potable water applications.

It’s important to ensure that all components of your reverse osmosis system, including the tank valve, are certified for drinking water use. This certification helps maintain the purity and safety of your water supply.

Yes, installing a Reverse Osmosis (RO) tank valve is generally straightforward and can be accomplished with basic tools. Here’s a step-by-step guide to assist you:

-

Shut Off the Water Supply: Locate and close the cold water feed valve that supplies water to your RO system.

-

Drain the RO Tank: Open the RO faucet to release any remaining water from the tank, ensuring it’s fully emptied.

-

Disconnect the Tank Tubing: Identify the tubing connected to the existing tank valve. To detach it, press and hold the collet (a small ring) on the fitting while gently pulling the tubing out.

-

Remove the Old Tank Valve: Unscrew the existing valve from the tank’s threaded stem.

-

Prepare the New Tank Valve: Apply approximately four wraps of Teflon tape around the tank’s threaded stem to ensure a watertight seal.

-

Install the New Tank Valve: Screw the new valve onto the tank’s stem securely, but avoid over-tightening.

-

Reconnect the Tubing: Insert the tank tubing into the new valve’s fitting until it is fully seated.

-

Restore the Water Supply: Open the cold water feed valve to allow water to flow into the system.

-

Check for Leaks: Monitor the connections for any signs of leakage. If leaks are detected, ensure all fittings are tightened appropriately.

-

Allow the Tank to Refill: Wait approximately 3-4 hours for the tank to fill completely before resuming regular use.

The lifespan of a reverse osmosis (RO) tank valve can vary based on factors such as material quality, usage frequency, and maintenance practices. While specific data on tank valve longevity is limited, it’s noteworthy that well-maintained RO systems can operate efficiently for 10 to 15 years.

Given that RO tanks are typically warrantied for 5 years but often last beyond that,

it’s reasonable to expect that a high-quality tank valve, when properly maintained, could have a comparable lifespan.

To maximize the longevity of your RO tank valve:

-

Regular Maintenance: Periodically inspect the valve for signs of wear or corrosion and ensure it operates smoothly.

-

Proper Installation: Ensure the valve is correctly installed to prevent undue stress or damage.

-

Timely Replacement: If you notice any issues such as leaks or difficulty in operation, consider replacing the valve promptly to maintain the system’s integrity.

By adhering to these practices, you can help ensure the tank valve remains functional throughout the lifespan of your RO system.

Only logged in customers who have purchased this product may leave a review.

العربية

العربية Zoom 3.2-Gallon Pressure Tank for RO Systems

Zoom 3.2-Gallon Pressure Tank for RO Systems

Reviews

There are no reviews yet.