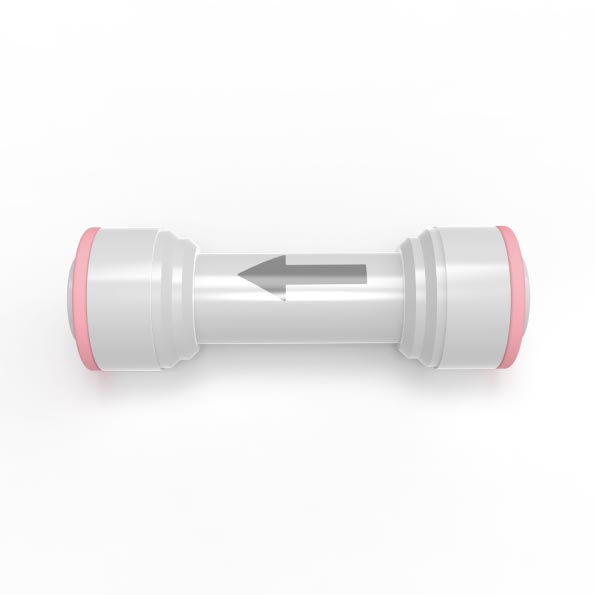

Non Return Valve

1,0 ر.ع.

The Non-Return Valve (NRV) in reverse osmosis systems prevents water from flowing back into the membrane, protecting it from damage and extending its lifespan. It ensures one-way water flow, maintains consistent pressure, and enhances the system’s filtration efficiency and overall performance.

In a Reverse Osmosis (RO) system, a Non-Return Valve (NRV) plays a crucial role in ensuring the efficiency and proper functioning of the system. typically installed on the permeate line to prevent the backflow of water into the membrane.

This backflow could potentially damage the membrane or reduce its lifespan.

By allowing water to flow in only one direction, the NRV maintains consistent pressure within the system, improves filtration performance, and ensures the longevity of the RO components. It’s a vital component for optimal water purification.

FAQs

In Zoom Oman’s Reverse Osmosis (RO) systems, the Non-Return Valve (NRV) serves a vital function by ensuring unidirectional water flow. Specifically, it prevents purified water from flowing back into the RO membrane, thereby protecting it from potential damage and extending its lifespan. By maintaining consistent pressure and allowing water to flow in only one direction, the NRV enhances the system’s filtration efficiency and overall performance.

In Reverse Osmosis (RO) systems, the Non-Return Valve (NRV), also known as a check valve, is essential for maintaining system integrity and performance. Its importance can be summarized as follows:

-

Prevents Backflow: The NRV ensures that water flows in only one direction—from the RO membrane to the storage tank. This prevents purified water from flowing back into the membrane, which could damage it and reduce its lifespan.

-

Maintains System Pressure: By allowing unidirectional flow, the NRV helps maintain consistent pressure within the system. This consistent pressure is crucial for optimal filtration performance and efficiency.

-

Enables Automatic Shutoff Functionality: In systems equipped with an automatic shutoff valve (ASV), the NRV plays a critical role. It provides the necessary back pressure that allows the ASV to function correctly, stopping the system from producing water when the storage tank is full. Without a properly functioning NRV, the ASV may not operate as intended, leading to continuous water production and potential wastage.

By performing these functions, the NRV ensures that the RO system operates efficiently, maintains water quality, and extends the lifespan of critical components.

Yes, replacing the Non-Return Valve (NRV), or check valve, in a Reverse Osmosis (RO) system is generally straightforward and can often be done without professional assistance. Here’s a step-by-step guide to help you through the process:

-

Identify the Check Valve Type and Location:

- In many RO systems, the check valve is integrated into the elbow fitting connected to the membrane housing’s permeate (product water) port. This is typically a small, often white, elbow fitting.

-

Turn Off the Water Supply:

- Ensure the main water supply to the RO system is turned off to prevent any water flow during the replacement.

-

Depressurize the System:

- Open the RO faucet to release any built-up pressure within the system.

-

Disconnect the Tubing:

- Carefully disconnect the tubing from the check valve’s fitting. If your system uses quick-connect fittings, you can do this by pressing down on the collet (the small ring around the tubing entry point) and gently pulling the tubing out.

-

Remove the Old Check Valve:

- Unscrew or pull out the old check valve from the membrane housing, depending on its design.

-

Install the New Check Valve:

- Insert and secure the new check valve into the membrane housing’s permeate port. Ensure it’s properly seated to prevent leaks.

-

Reconnect the Tubing:

- Insert the tubing back into the new check valve’s fitting until it seats firmly.

-

Turn On the Water Supply:

- Gradually turn the main water supply back on.

-

Check for Leaks:

- Observe the system closely for any signs of leaks around the new check valve and fittings.

-

Test the System:

- Allow the system to pressurize and monitor its operation to ensure everything functions correctly.

Only logged in customers who have purchased this product may leave a review.

العربية

العربية

Reviews

There are no reviews yet.